Manufacturing

- Simplified data in a user-friendly interface

- Reduce employee loss and increase retention

- Reduced train-up times by 90%

- Increased productivity by 24%

- A swift Return on Investment

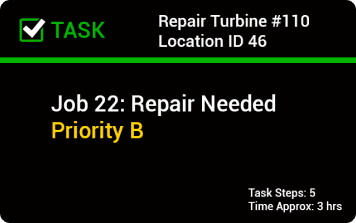

Guide your workers in the manufacturing process with Plug and Play HUDs

Our HUDs provide workers on product manufacturing lines with information displayed right in their field of view to ensure better quality and faster assembly times. Implementing Augmented Reality in your manufacturing process substantially improves workers’ performance and ensures fewer human errors occur on the production line, with a quick and notable return on investment.

- Rugged Design

- Comfort

- Adaptability for Any Worker

- Easy to Use

- Simple to deploy

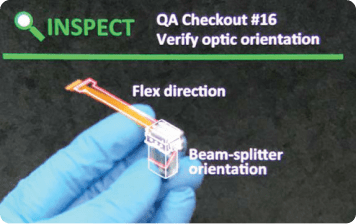

In addition to all the ST1™ features, the ST1-C™ allows users to perform camera-enabled tasks:

- Remote Assistance

- Hands-Free Video Capture

- Photo Documentation

Start using it TODAY with immediate results.

Six15 ST1™ and ST1-C™ Head-Up Display

Complement your HUDs with accessories and provide your workforce with an ideal AR experience.

Technical Specifications

Download the ST1™ Data Sheet-

DisplayFull Color OLED; 640 x 400 pixels

-

Field of View20.30 diagonal

-

Eye Box7.5 x 9 mm

-

Eye Relief18 mm

-

Brightness300 cd/m²

-

*Camera (ST1-C only)5 MP, fixed focus

-

Head Tracker9-axis integrated sensor

-

AudioIntegrated microphone

-

ConnectivityUSB 2.0

-

Host Device ConnectivityAndroid (5.0 and higher) and Windows 10

-

FrameESS Crosshair ONE Frame (ANSI Z87.1+)

-

Weight (without cable)<1.06 oz./<30g

-

SealingIP67 (waterproof and dustproof)

-

Drop6 ft/1.8m (to concrete)

-

Operating Temperature-40 F to 1580 F / -200 C to 700 C

As incumbent manufacturing gets more and more disrupted because of geopolitical externalities, new sources are emerging to keep up with demands – workers are essential for the manufacturing process, and the need to minimize human errors and ensure product quality is a challenge for most manufacturing companies.

By implementing Augmented Reality in your manufacturing process, you automatically reduce your employee workload and pressures and ensure a better manufacturing process with fewer human errors. Not tomorrow. Today.

Our AR Head-Up Displays provide guided assemblies for workers on product manufacturing lines by displaying all relevant information on the process right in their field of view, leaving their hands free to execute their tasks – this enables them to perform better while at the same time reducing work pressures and cognitive loads.

Our devices have been designed to be ergonomic and fully customizable to provide an optimal viewing experience for the worker without physically burdening them in any way, with a significant increase in performance.

Augmented Reality in the manufacturing sector offers faster onboarding times and eliminates the use of conventional paper manuals. New workers can immediately start their duties on the manufacturing lines through clear instructions in real-time in their field of view.

We aimed to create a device that can be tailored to manufacturing needs to provide workers with an intuitive learning process that eliminates errors, reduces workload, and eases learning.

Implementing AR in your manufacturing and production process immediately provides a significant return on investment – new workers on the manufacturing lines can be easily trained and immediately start working.

Fewer human errors occur, resulting in a substantial improvement in overall employee performance and retention.

A near-instant return on investment, with clear and tangible results visible in weeks.

Training Time

Worker Productivity

Return On Investment

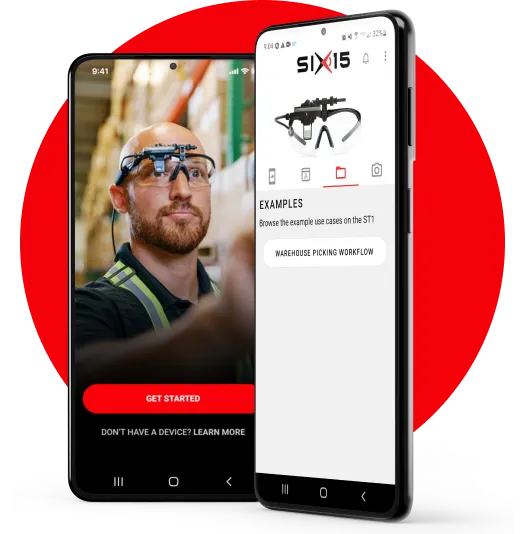

Six15 ST1

This app demonstrates the capabilities of the ST1™ Head-Up Display (HUD) when connected to a smartphone device.

- Screen Mirror

- Intent Interface

- Warehouse Picking Demo

- Camera Demo (on ST1-C hardware)

- Firmware Update

- IMU Calibration

- Allows other HUD-enabled apps to access the ST1